I was curious about the temperature profiles of my hot water tank as it was being heated by my natural gas powered water heater ("boiler" or "furnace"). As is normal in Ireland, household hot water is provided from hot water storage tank which is heated via heat exchanger by the central heating system.

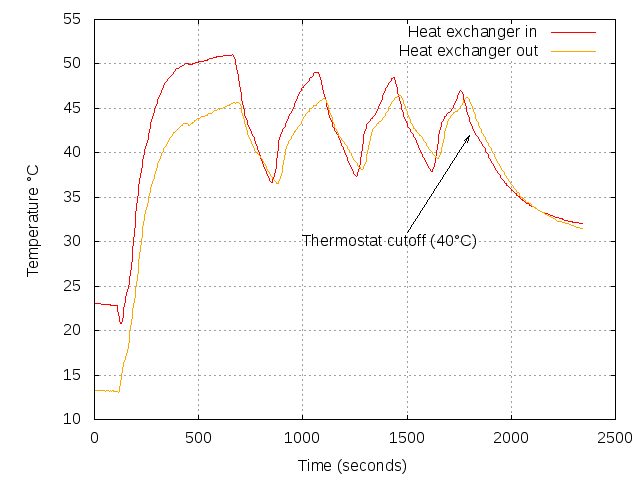

The following is the temperature at the heat exchanger inlet and outlet of the hot water tank. Temperature was measured with DS18B20 temperature sensors which were taped to the pipe near the tank.

A few things struck me as being interesting about this graph. First there is a brief but noticeable dip in inlet temperature when the system is first switched on. This is clearly the cold water ahead of the pump/heater entering the heat exchanger. There is a quick rise in temperature with the outlet temperature following the input minus a temperature drop (due to heat transferred to the water in the tank) and a time lag (due to the transit time of water in the heat exchanger). However the most striking feature is the temperature cycling.

It seems that my heater cannot transfer heat to the tank fast enough. The water in the heat exchanger circuit reaches the heater's target water flow temperature (user settable from 30°C-85°C) and the flame cuts off. The pump continues to pump until the temperature drops below some threshold and the cycle repeats. The duty cycle is about 50 seconds flame on, and 180 seconds flame off.

There is another interesting effect during the cooling phase: a brief increase in temperature for about 30 seconds before dropping again. I believe this artifact is because the heater flame is on for less time that it takes for the water to circulate around the system. So there is a hot spot which makes a second round through the system.

I re-ran the experiment with a higher heater temperature:

It looked identical (excepted at elevated temperatures). But only when I looked at the numbers more closely while writing this post did I realize that the period between cycles had increased from about 230 seconds to 330 seconds. So perhaps if I set the heater at the max temperature I could increase the period to a sufficiently long time to heat the water in the tank in just one cycle.

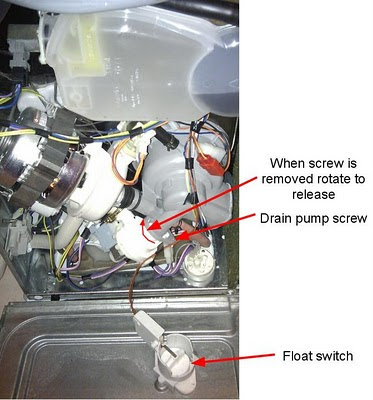

The following graph is from a third run. This time the heater was set at the max temperature (supposedly 85°C) and I set the tank thermostat at 40°C.

Unfortunately there was still cycling, 4 in total, but the cycle period was considerable longer than any than the previous runs. More importantly the duty cycle was much better: 500 seconds of flame on, 100 seconds flame off for the first cycle; 220s on/100s off for second, 180s on / 100s off for third, and 140s on for the last cycle. The tank thermostat cut off the heater at about 1800 seconds (30 minutes) into the experiment.

Conclusion:

For fast hot water, running the heater as hot as possible works best (at least for me). At some point the heater temperature must have been turned low which explains why in recent years it seems to be taking ages for the water to heat. However all this probably makes no difference to the energy efficiency of the system.

.jpg)